Double side PVC waterproof anticorrosion Tape

Basic Info

Model No.: T400

Product Description

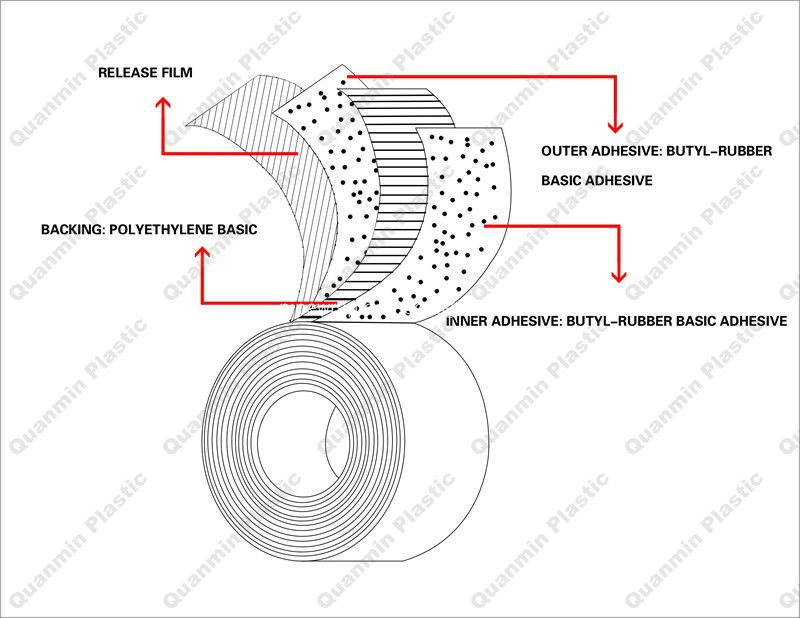

Double Sides anticorrosion Tape , 3ply PE Tape,

Applications

3plyPE is extensively used in the pipe work of oil and natural gas transportation, petrochemical industry, electric power, metallurgy, urban natural gas network of pipes, the outside anticorrosion project of the metal pipes involved as well as the outside anticorrosion project of the underground and overhead metallic conduit of the works of petrochemical industry, natural gas and coal transportation

It always be called Self-adhesive flashing tape, Mastic tape, and PE double-side anticorrosion tape.

Features & Benefits

Containing adhesive layer of proper thickness, it is of super healing and insulating performance.The binding force between the backing material and adhesive layer is great, which will prevent degumming.

It is of high thermal aging resistance and UV resistance.

It has high tensile strength and appropriate elongation at break, which makes the mechanical and manual wrap easier.

It has varieties, specifications, and colors of all kinds, including anticorrosion tape (inner tape), protective tape (outer tape), joint wrap tape, etch primer as well as the necessary tools.

Long term corrosion protection and mechanical resistance

Outstanding electric property and permanent adhesion

Excellent weather & cold resistance

Complies with AWWA C-209 & C-214 ,DIN30670,Standard Product Construction

Adhesive: Butyl Rubber

Text Data sheet:

| Properties |

Test Method | T476-30 | T481-32 | ||

| Metric | English | Metric | English | ||

| Total Thickness | ASTM D 1000 | 0.770mm | 30 mils | 0.830mm | 32 mils |

| Adhesive Thickness(External) | ASTM D 1000 | 0.250mm | 10 mils | 0.160mm | 6 mils |

| Adhesive Thickness(Internal) | ASTM D 1000 | 0.260mm | 10 mils | 0.360mm | 14 mils |

| Backing Thickness | ASTM D 1000 | 0.260mm | 10 mils | 0.310mm | 12 mils |

| Tensile Strength | DIN 30672/1 | 64.5 N/cm | 36.3 lbs/in | 72 N/cm | 41.2 lbs/in |

| Elongation | DIN 30672/1 | 510% | 510% | 570% | 570% |

| Shear Resistance | DIN 30672/1 | 0.054 N/mm2 | 125 oz/sqin | 0.060 N/mm2 | 139 oz/sqin |

| Peel strength to Primed Steel at (180 º) | |||||

| At 23 ºC | DIN 30672/1 | 18 N/cm | 165 oz/in | 20 N/cm | 183 oz/in |

| At 50 ºC | DIN 30672/1 | 2.4 N/cm | 22 oz/in | 2.7 N/cm | 25 oz/in |

| Peel strength outer layer to inner layer(180 º) | |||||

| At 23 ºC | DIN 30672/1 | 36 N/cm | 329 oz/in | 45 N/cm | 411 oz/in |

| At 50 ºC | DIN 30672/1 | 4.8 N/cm | 44 oz/in | 6.0 N/cm | 55 oz/in |

| Water Absorption | ASTM D 570 | 0.06% | 0.06% | 0.05% | 0.05% |

| Water Vapor Transmission Rate (24h) | ASTM E 96 | 0.13g/m2·24h | 0.083g/100sq in/24h | 0.075g/m2·24h | 0.005g/100sq in/24h |

| Insulation Resistance | ASTM D 257 | 108 Mohm | 10E 8 Mohm | 1010 Mohm | 10 E10Mohm |

| Dielectric Strenght | ASTM D 1000 | 41 KV/mm | 1041volts/mil | 43 KV/mm | 1092volts/mil |

| Impact Resistance | DIN 30672/1 | 15.3 N·m | 15.3 Joules | 15.5 N·m | 15.5 Joules |

| Color | Black | ||||

| Tape width in inches | 50mm(2″),101mm(4″),152mm(6″),228mm(9″),305mm(12″),457mm(18″), | ||||

| Tape roll length in feet | 15m(50ft),25m(82ft),30m(98ft),50m(164ft),61m(200ft),100m(328ft),122m(400ft),183m(600ft),244m(800ft) | ||||

| Core size | 38mm(1.5″).76mm(3″) core of paper or hard plastic | ||||

| Application Temperature | -34 ºC to +85 ºC ( -29 ºF to 185 ºF ) | ||||

| Operating Temperature | +85 ºC ( 185 ºF ) | ||||

|

Phisical Properties |

Test Method | T4100-40 | T4110-43 | ||

| Metric | English | Metric | English | ||

| Total Thickness | ASTM D 1000 | 1.01mm | 40 mils | 1.10mm | 43.5 mils |

| Adhesive Thickness(External) | ASTM D 1000 | 0.25mm | 10 mils | 0.41mm | 16 mils |

| Adhesive Thickness(Internal) | ASTM D 1000 | 0.50mm | 20 mils | 0.50mm | 20 mils |

| Backing Thickness | ASTM D 1000 | 0.26mm | 10 mils | 0.19mm | 7.5 mils |

| Tensile Strenght | DIN 30672/1 | 71 N/cm | 40.5 lbs/in | 70 N/cm | 40.0 lbs/in |

| Elongation | DIN 30672/1 | 550% | 550% | 530% | 530% |

| Shear Resistance | DIN 30672/1 | 0.060 N/mm2 | 139 oz/sqin | 0.060 N/mm2 | 139 oz/sqin |

| Peel strength to Primed Steel at (180 º) | |||||

| At 23 ºC | DIN 30672/1 | 28 N/cm | 256 oz/in | 28 N/cm | 256 oz/in |

| At 50 ºC | DIN 30672/1 | 3.7 N/cm | 33.8 oz/in | 3.7 N/cm | 33.8 oz/in |

| Peel strength outer layer to inner layer(180 º) | |||||

| At 23 ºC | DIN 30672/1 | 50 N/cm | 457 oz/in | 55 N/cm | 503 oz/in |

| At 50 ºC | DIN 30672/1 | 6.6 N/cm | 60.3 oz/in | 8.5 N/cm | 77.7 oz/in |

| Water Absorption | ASTM D 570 | 0.05% | 0.05% | 0.05% | 0.05% |

| Water Vapor Transmission Rate (24h) | ASTM E 96 | 0.075 g/m2·24h | 0.05 g/m2·24h | 0.075 g/m2·24h | 0.05 g/m2·24h |

| Insulation Resistance | ASTM D 257 | 1012Mohm | 10 E12 Mohm | 1014Mohm | 10 E14 Mohm |

| Dielectric Strenght | ASTM D 1000 | 43 KV/mm | 1092 volts/mil | 45 KV/mm | 1143 volts/mil |

| Impact Resistance | DIN 30672/1 | 15.3 N·m | 15.3 Joules | 15.5 N·m | 15.5 Joules |

| Color | Black | ||||

| Tape width in inches | 50mm(2″),101mm(4″),152mm(6″),228mm(9″),305mm(12″),457mm(18″), | ||||

| Tape roll length in feet | 15m(50ft),25m(82ft),30m(98ft),50m(164ft),61m(200ft),100m(328ft),122m(400ft),183m(600ft),244m(800ft) | ||||

| Core size | 38mm(1.5″).76mm(3″) core of paper or hard plastic | ||||

| Application Temperature | -34 ºC to +85 ºC ( -29 ºF to 185 ºF ) | ||||

| Operating Temperature | +85 ºC ( 185 ºF ) | ||||

Application

1 Rust Removal

Steel Surface needs treating. Its quality shall reach Sa2 or St3 grade as prescribed in GB8923-88 Pre-paint Steel Surface Rust Grade and Rust-removal Grade, and it shall be dust-free.

2 Priming

Primer shall be stirred well before painting. An even film of primer is painted on the steel surface that is rust-removed completely and dust-free. After the primer dries up (one may feel no sticky). The steel pipe can be wrapping with tape (it usually takes 3 to 5 minutes). The primer dosage usually amounts to 80 to 100g / m².

3 Inner Tape (Anti corrosion Tape) & Outer Tape (Protection Tape) Wrapping

The steel pipe that is painted with primer is wrapping with tape by means of suitable devices or tools as per joint needs, and wraps the inner tape and then wraps the outer tape. Tape tensibility can be 10 to 20 N / cm. The overlapped length between beginning and end of an adhesive tape shall be no less than 1/4 circumference of the steel pipe and the total length of adhesive tape shall be no less than 100mm. each film shall be paralleled, and must not be twisted and rumpled.

TRADE TERMS:

1 Payment: 30% T/T DEPOSIT PAYMENT IN ADVANCE, BALANCE AGAINST COPY OF B/L, WESTERN UNION, ESCROW, L/C.

2 Production Lead Time: 10 - 15 DAYS AFTER DEPOSIT PAYMENT.

3 Shipping Methods: OCEAN FREIGHT / AIR FLIGHT /COURIER PRESS

4 FOB Shipping port: QINGDAO, SHANGHAI ,OTHER PORTS, MAINLAND CHINA.

5 If you want to deal with EXW/CIF/CNF term instead of FOB, please specify. Otherwise, FOB price will be quoted under inquiry.

OUR SERVICE:

· Your inquiry related to our product & price will be replied within 24hours.

· Well-trained & experienced staffs are to answer all your inquiries in English of course.

· Working time: 8:30am - 6:00pm, Monday to Saturday (UTC+8).

· OEM & ODM projects are highly welcomed. We have strong R&D team here to help.

· Your business relationship with us will be confidential to any third party.

· Good after-sale service offered, please get back if you got question.

Product Categories : Anticorrosion Pipe Wrap Tape > Double Side Tape