WKS-120 PVC Compounds Extruder Machine

| Payment Type: | L/C,T/T,Money Gram,Western Union |

|---|---|

| Terms of Trade: | FOB,EXW |

| Min. Order: | 1 Piece/Pieces |

| Delivery Time: | 60 Days |

| Packaging: | Wood Box and Pallet |

|---|---|

| Productivity: | 5-1800KG/H |

| Brand: | XINDA |

| Transportation: | Ocean |

| Place of Origin: | Jiangsu,China |

| Supply Ability: | 1000 |

| Certificate: | ISO9001,CE,SGS |

| HS Code: | 84772010 |

| Port: | SHANGHAI,QINGDAO,NINGBO |

Basic Info

Model No.: WKS

Click on the follow link to find out more information: https://www.xindaextruder.com/wks-serial-co-kneader/

Company Info

- Company Name: JIANGSU XINDA TECH LIMITED

- Representative: Kong Xiangming

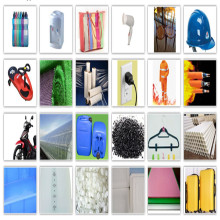

- Product/Service: Co kneader , Twin Screw Extruder , Mixer / blender , Extruder Spare Parts , Plastic Recycling Line , Compounding extruder

- Capital (Million US $): US$16 Million

- Year Established: 1996

- Total Annual Sales Volume (Million US $): US$5 Million - US$10 Million

- Export Percentage: 71% - 80%

- Total Annual Purchase Volume (Million US $): US$1 Million - US$2.5 Million

- No. of Production Lines: above 20

- No. of R&D Staff: 21 -30 People

- No. of QC Staff: 5 -10 People

- OEM Services Provided: yes

- Factory Size (Sq.meters): 30,000-50,000 square meters

- Factory Location: No.3-1, Huandong Road Xiake Town, Jiangyin City,jiangsu P.R CHINA

- Contact Person: Mr. Kedan

- Tel: 00-86-17368356450

Premium Related Products

Other Products

Hot Products

Din 6899b heavy duty cable thimbleRatched chain load binder with hooksOblong master linkHigh strength drop forged JIS1168 eye boltPolished JIS1169 eye nutAlloy steel electric clevis grab hookHigh holding power marine anchor for saleOval cable aluminium wire rope ferrulesAnchor chain swivelElectrical Galvanized wire gripDin 1480 small drop forged turnbuckleGalvanized used steel wire ropeEuropean drop forged safety bow shackleAnchor chainGalvanized melded iron link chainCarabiner spring snap hook clip